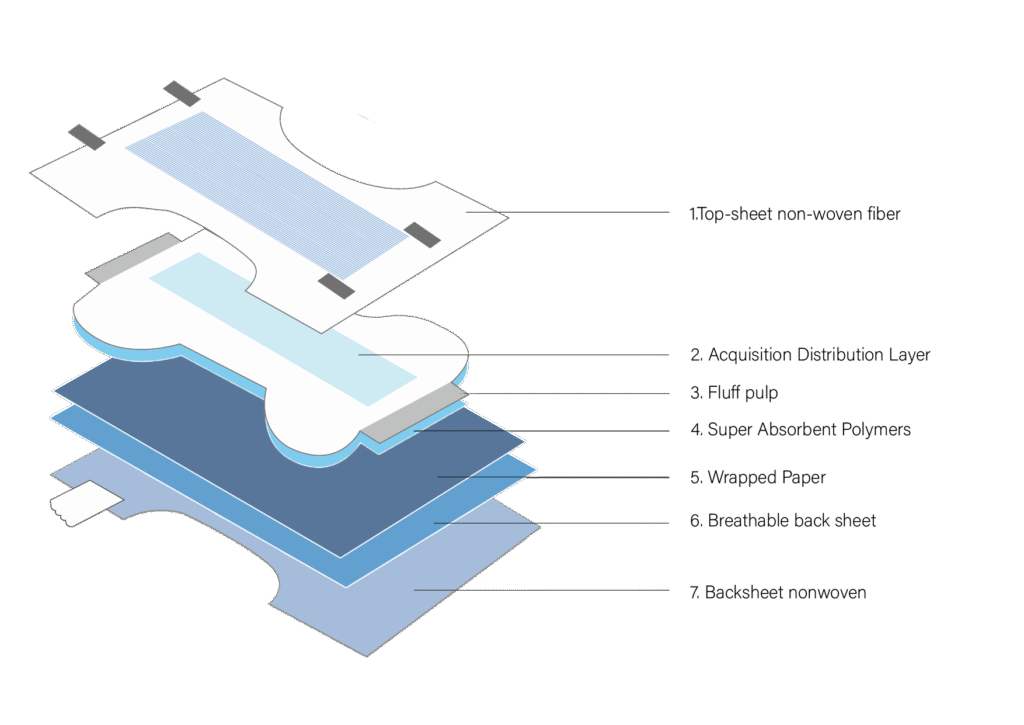

In the competitive landscape of absorbent hygiene products, achieving optimal performance while maintaining comfort and cost-effectiveness is a constant challenge. Traditional diaper core designs often compromise on absorbency to address concerns about Super Absorbent Polymer (SAP) containment, resulting in bulky products and diminished user satisfaction. WEHOO’s DRY-Hoo™ technology revolutionizes the pulp core paradigm, achieving unprecedented levels of SAP ratio and unlocking a new standard in absorbency, dryness, and overall product performance.

The Challenge: Traditional Pulp Cores and the SAP Dilemma

Conventional wood pulp cores in baby diapers and adult incontinence products typically combine wood pulp and SAP. However, manufacturers often prioritize wood pulp due to concerns about managing and containing the SAP, resulting in lower SAP ratios (below 45%).

This imbalance has several drawbacks:

- Reduced Absorbency: Lower SAP ratios directly translate to reduced overall absorbency capacity.

- Increased Bulk: Higher wood pulp content leads to thicker, bulkier cores, compromising comfort and fit.

- Compromised Dryness: Inefficient SAP utilization results in a slower absorption rate and a greater risk of re-wet, leading to discomfort and potential skin irritation.

The DRY-Hoo™ Advantage: Unlocking the Power of High SAP Ratios

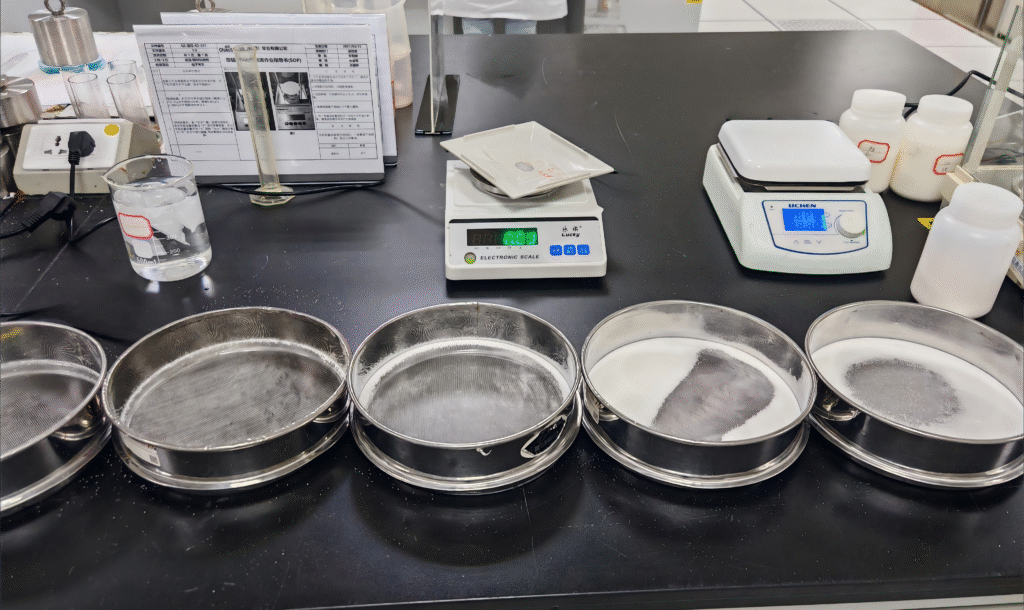

DRY-Hoo™ takes a fundamentally different approach. Our proprietary technology enables us to achieve SAP ratios approaching 1:1 within the core, maximizing the potential of SAP and transforming the performance characteristics of absorbent hygiene products. This is achieved through extensive research of all commercially available Super Absorbent Polymers, allowing us to identify the optimal combination and ratio for superior performance.

Benefits of the DRY-Hoo™ Technology

| Feature | Benefit |

|---|---|

| High SAP Ratio (Approaching 1:1) | Significantly increased absorbency capacity |

| Optimized SAP Distribution | Faster absorption rates, reduced re-wet, enhanced dryness |

| Reduced Wood Pulp Content | Thinner, more flexible cores, improved comfort and fit |

| Enhanced Core Integrity | Better fluid management, minimized leakage, consistent performance |

How DRY-Hoo™ Redefines Core Performance

DRY-Hoo™ addresses the limitations of conventional cores through:

- Proprietary SAP Containment Technology: Our innovative approach ensures secure and efficient SAP containment, enabling high SAP ratios without compromising product integrity.

- Optimized SAP Distribution: DRY-Hoo™ technology promotes uniform SAP distribution throughout the core, maximizing its effectiveness in absorbing and retaining fluid.

- Engineered Core Structure: The DRY-Hoo™ core structure is carefully engineered to optimize fluid flow and distribution, further enhancing overall performance.

The Impact of DRY-Hoo™: A Win-Win for Manufacturers and Consumers

By integrating DRY-Hoo™ technology into your absorbent hygiene products, you can:

- Offer Superior Performance: Provide consumers with products that deliver exceptional absorbency, dryness, and comfort.

- Differentiate Your Brand: Gain a competitive edge with a technology that redefines the standards for pulp core performance.

- Optimize Material Usage: Reduce wood pulp content while maximizing SAP utilization, potentially leading to cost savings.

DRY-Hoo™ represents a new approach to absorbent core design, and we anticipate continued advancements in this area to further enhance product performance and consumer satisfaction.